Our offer

Frozen block crusher KBM-600

Highly industrial machines designed for crushing of individually loaded frozen blocks of meat, fish, cheese, vegetables or other food products with standard euro-block dimensions. The best efficiencies are available with temperature of products in the range from – 15 to – 20 C.

Frozen block crusher KBM-600 – operation

Crushing of the frozen blocks is executed with the help of slow speed, strong resistant, robust tooth head. Despite cutting effect with the dimensions that are close to the teeth width, the structure of the product is partially restored to the size of elements before freezing. That especially concerns meat raw materials. Used cutting systems do not raise the temperature of the product.

Frozen block crusher KBM-600 – options

After cutting smaller pieces of the frozen product can go directly into the trolley or on conveyer that transports them for further grinding and processing, usually with the help of machines such as grinder, cutter or mixer.

Industries

-

Meat, poultry

-

Fishes

-

Cheese

-

Warzywa i owoce

Technical data

Additional equipment

- Column loading model ZM-200B for blocks

- Belt conveyer model ZT-B for blocks with optional side table

- Unloading of the shredded product can be adjusted with the help of special hoppers sealing and protecting the discharge at the same time for 200 and 300 ltr containers and big-boxes.

-

Width or the cutting head teethfrom 35 to 70 mm

-

Efficiencyfrom 3000 to 6000 kg/h*

-

Estimated grinding time1 block per 10 sec

-

Block sizesmax. 400x600 mm, height from 80 to 250 mm

-

Standard loadingchute on gas cyllinders for loading blocks, with special angle in order to load the block directly into the cutting head

-

Drive power18,5 kW

-

Cutting head speed44 RPM

-

Standard unloading heightfor 200 l with blockade and trolley presence sensor

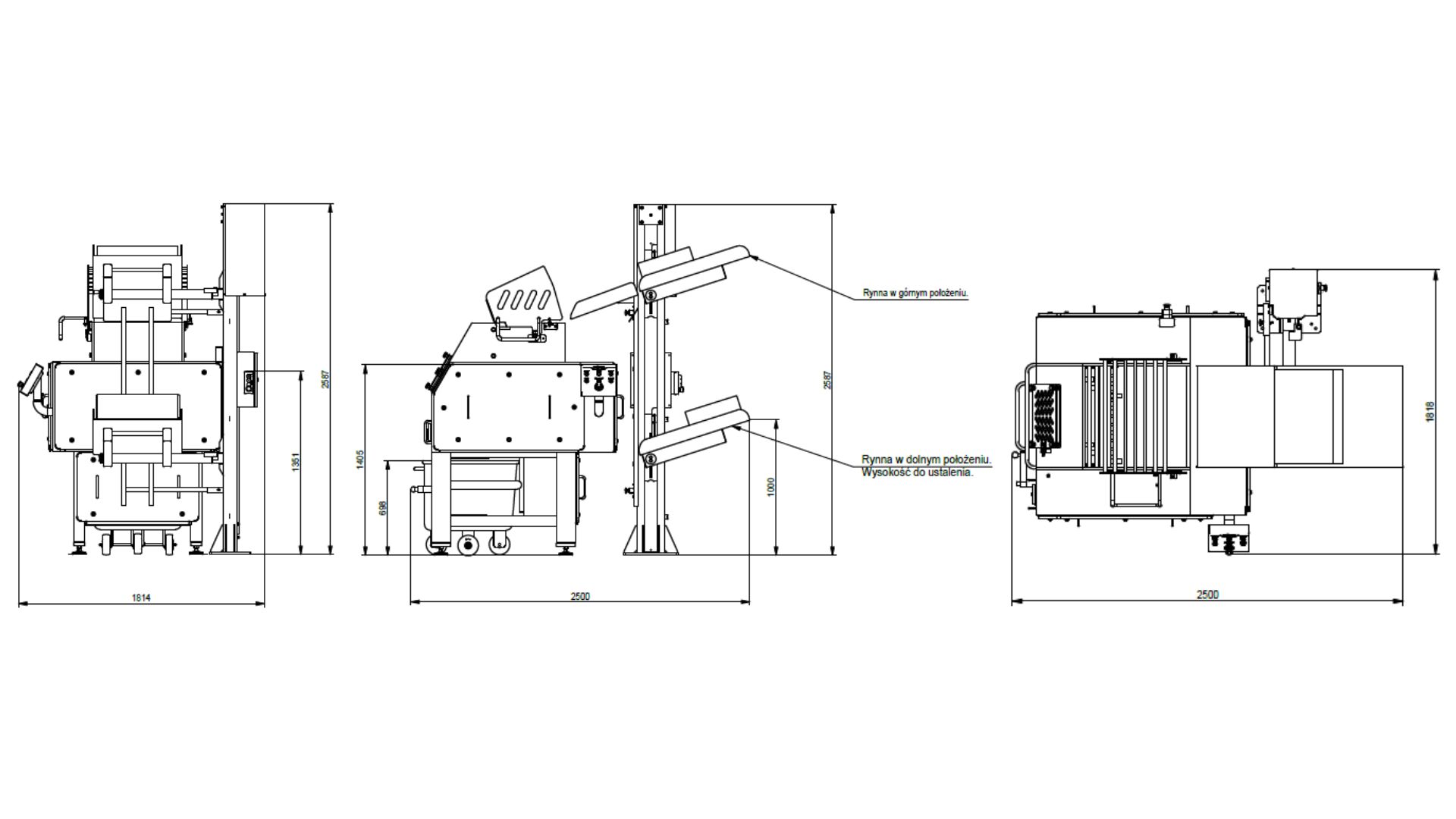

Dimensions

Ourpartners

Our

Awards