Our offer

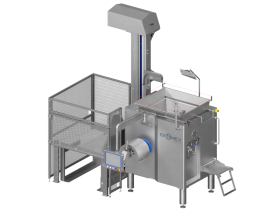

Automatic angle grinder with separating head WW-160

The automatic angle grinder is available in the version pre-prepared for the Singriset separating head, which is the original, patented system for extruding meat raw materials with automatic adjustment of the separation pressure.

Features of automatic angle grinder with separating head WW-160

Such a configured machine becomes a universal and effective low- and high-pressure separator, largely eliminating harder fractions such as: tendons, cartilages, gristles, , bones, hard fat, veins, during the process of grinding meat into a structure from 2 to 7 mm.

When grinding fresh, slightly frozen meat, hard cheeses, the Singriset system can replace the traditional cutting sets based on knives and hole plates.

In terms of the diameter of the sleeve holes 2 ÷ 4/3 ÷ 5/5 ÷ 7 mm, it additionally enables:

– separation of poultry bones (chicken, turkey),

– hole separation of cartilages, pork and beef skins,

– grinding and cleaning cooked meat (culinary meat).

Appropriate construction of the hopper, housing, angular positioning of the screws (feeding and working), their appropriate construction, speed adjustment and speed difference provide even flow of the raw material and good compression on the cutting tools, what provides the proper structure of the cutting.

PLC control in automatic angle grinder

PLC control enables motor load control, clear operation, current adjustment, programming, archiving and saving of program parameters on the touch panel.

Industries

-

Meat, poultry

-

Fishes

-

Cheese

-

Dania gotowe

-

Pet food

-

Warzywa i owoce

Technical data

Features of Ekomex grinders:

- Robust, massive, smoothly polished construction made of stainless steel EN 1.4301.

- Hygienic and ergonomic design provides easy operation, cleaning and maintenance.

- High quality components

Additional equipment:

- Smooth adjustment of the screws speeds

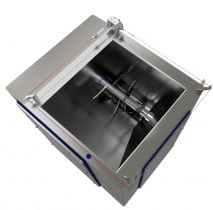

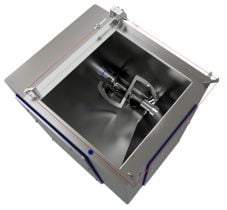

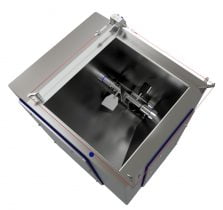

- VERTICUT system – horizontal knife shaft for initial grinding of frozen blocks to -10 ° C, installed in the hopper.

- VERTIMIX system – horizontal paddle or Z-type mixing shaft – placed above the feeding screw, which works in the REVERSE mode during the PREMIX cycle. These systems have been developed to increase the range of operation of the machine as well as to improve the uniformity of the feeding the raw material towards the feeding screw.

- Column loading ZM200 for 200 l bins or type ZM-600 for BIGBOX containers

- Individual unloading height

- Control panel on the arm

-

ModelWW-160 / S5000

-

Standard hopper capacity500 / 800 l

-

Cutting toolsØ 160 mm [G160] / Singriset GO-GS160

-

Configuration of cutting tools:2 ÷ 5 parts

-

Feeding screw drive power1,5 / 1,9 kW

-

Main screw drive power26 / 37 kW

-

PLC controltouch screen

-

Tool removal leverhydraulic

-

Capacityup to 6000 kg/h depending on raw material, its temperature and cutting tools

-

Unloading heightfor 200 l bins

-

Multi-stage screw sealingrinsing channel

-

Screw housingCNC machined inner channels

-

Control panel and control unitPLC

Dimensions

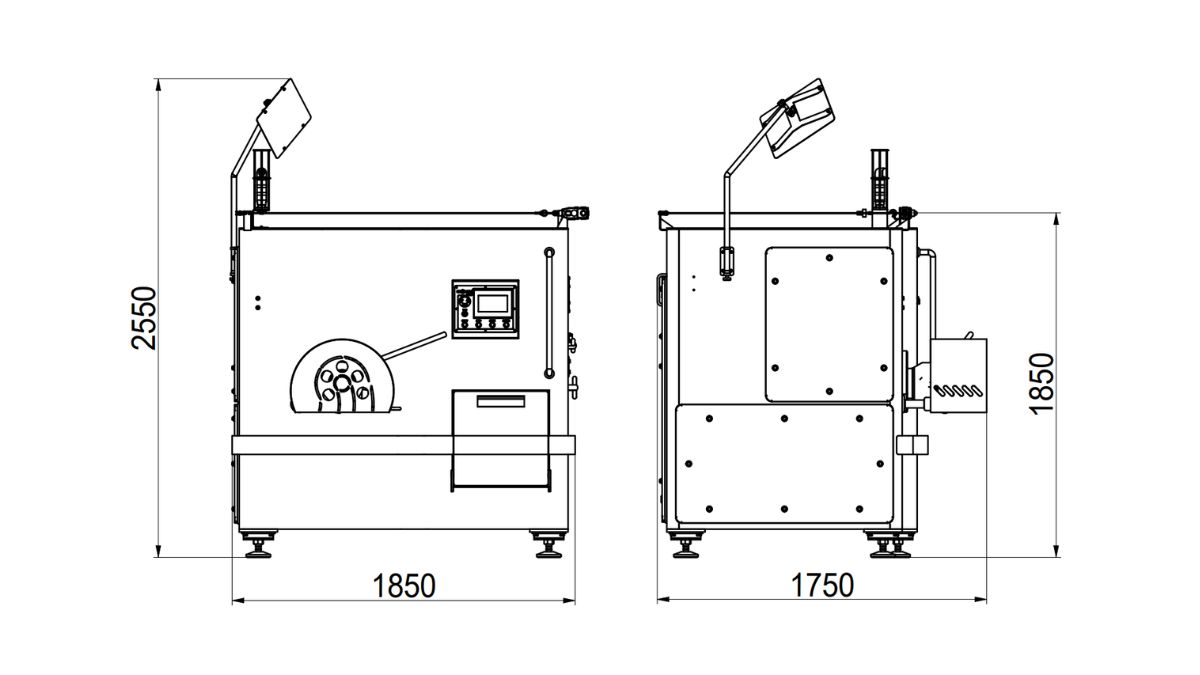

Dimensions of automatic angle grinder WW-160

Ourpartners

Our

Awards